Introduction to Mohs Hardness Scale: Understanding Mineral Scratch Tests

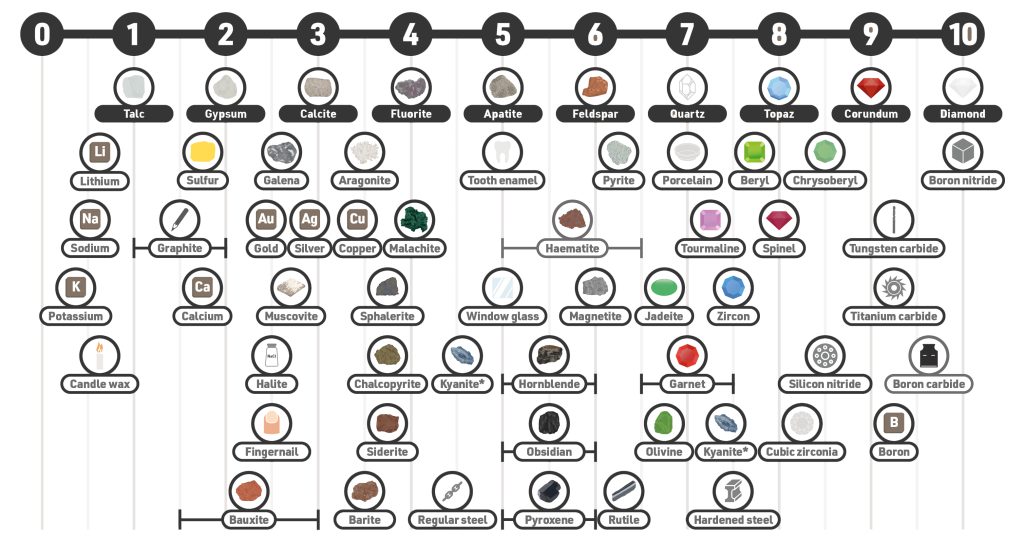

Delving into the world of geology, there’s a fascinating tool that has held the test of time in evaluating the hardness of minerals. Welcome to the realm of the Mohs Hardness Scale. This simple yet effective method, based on a mineral’s ability to scratch another, has been a cornerstone for professionals and enthusiasts alike. But what is it about the scratch test that has made this scale so invaluable?

The beauty of the Mohs Hardness Scale lies in its simplicity. Unlike many other scientific measures, the scratch test is visually straightforward. If Mineral A can scratch Mineral B, it’s harder. If not, it’s softer. Simple, right? Well, while the concept is uncomplicated, its applications and implications run deep, offering insights into the very nature of the Earth’s treasures.

Whether you’re a seasoned gemologist, an aspiring geology student, or just someone intrigued by the wonders of the Earth, the Mohs Hardness Scale offers a clear window into the resilience and characteristics of minerals. Let’s embark on this enlightening journey, unraveling the nuances of mineral hardness, and uncovering its significance in various industries and practical applications.

Origins and History: The Creation of Mohs Scale by Friedrich Mohs

The story of the Mohs Hardness Scale is intrinsically tied to the life and works of its creator, Friedrich Mohs. Born in 1773 in the German city of Gernrode, Mohs embarked on a journey that would lead him to be an esteemed figure in mineralogy.

Early Years and Passion for Mineralogy

Friedrich Mohs began his academic pursuits at the University of Jena, delving deep into the subjects of chemistry, mathematics, and physics. However, it was under the guidance of renowned mineralogist Abraham Gottlob Werner at the Mining Academy in Freiberg that Mohs developed an unwavering passion for mineralogy. Werner’s influence was undeniable, pushing Mohs to approach the subject with rigorous observational methods.

Development of the Scale

In 1812, while stationed in Graz, Austria, Mohs introduced his mineral hardness scale. Recognizing the need for a consistent and systematic method to determine mineral hardness, he used the principle of one mineral’s ability to scratch another as a measure. Mohs carefully selected ten minerals that were easily distinguishable and widely available, ranging from the softest (talc) to the hardest (diamond).

This was not the first time the concept of comparing mineral hardness was entertained. However, Mohs’ systematic approach and keen selection of reference minerals set his scale apart, making it a mainstay in mineralogical studies.

Legacy and Later Years

Mohs continued his work, classifying minerals, teaching, and contributing to the field until his death in 1839. Today, his legacy lives on, not just through the Mohs Hardness Scale, but also through the numerous students he inspired and the countless mineralogists who, to this day, use his method as a foundational tool in their studies.

Through the annals of history, Mohs’ contribution stands out not for its complexity but for its sheer simplicity and effectiveness, reminding us that sometimes, the most impactful ideas are also the most straightforward.

Decoding the Scale: A Deep Dive into Each of the 10 Levels

The Mohs Hardness Scale is a relative scale, based on the ability of one mineral to scratch another. Each level represents a specific mineral used as a standard of hardness. Let’s delve into the details of each level, examining the minerals and understanding their characteristics.

| Hardness Level | Mineral | Characteristics |

|---|---|---|

| 1 | Talc | Known for its softness, talc is the baseline mineral on the Mohs scale. It can be scratched by all other minerals and is often used in cosmetics and as a lubricant. |

| 2 | Gypsum | A widely used mineral in the production of plaster and fertilizer, gypsum is harder than talc but can still be easily scratched by fingernails. |

| 3 | Calcite | A key component in limestone and marble, calcite reacts with acid and is often used in cements and mortars. |

| 4 | Fluorite | Popular for its fluorescent property, fluorite is used in the production of certain optical equipment and in the steel industry. |

| 5 | Apatite | A vital mineral for the fertilizer industry due to its phosphate content. Apatite is also found in human and animal teeth and bones. |

| 6 | Orthoclase Feldspar | Common in the Earth’s crust, orthoclase is used in the making of ceramics and glass. |

| 7 | Quartz | One of the most abundant minerals, quartz is renowned for its hardness and is used in various industries, including electronics and timekeeping. |

| 8 | Topaz | A precious gemstone, topaz is admired for its beauty and is also used in various industrial applications. |

| 9 | Corundum | The mineral behind rubies and sapphires, corundum’s high hardness makes it ideal for abrasive applications. |

| 10 | Diamond | Renowned as the hardest natural substance, diamonds are coveted gemstones and are also employed in various industrial cutting and grinding tools. |

The Mohs scale, through its ten minerals, provides an intuitive way to understand mineral hardness, from the soft talc to the unparalleled hardness of diamonds.

Table of 48 Popular Minerals: Their Mohs Hardness Detailed

Minerals are a fundamental component of Earth’s crust, contributing to the landscape’s diversity and beauty. Their hardness, determined using the Mohs scale, plays an essential role in various applications. Here’s a comprehensive table showcasing 50 of the most popular minerals and their corresponding Mohs hardness.

| Mineral Name | Mohs Hardness Scale |

|---|---|

| Talc | 1 |

| Graphite | 1-2 |

| Mica | 2-4 (depending on type) |

| Gypsum | 2 |

| Halite (rock salt) | 2.5 |

| Biotite | 2.5-3 |

| Muscovite | 2-2.5 |

| Kaolinite | 2-2.5 |

| Galena | 2.5 |

| Silver | 2.5-3 |

| Gold | 2.5-3 |

| Calcite | 3 |

| Copper | 3 |

| Azurite | 3.5-4 |

| Malachite | 3.5-4 |

| Dolomite | 3.5-4 |

| Barite | 3-3.5 |

| Fluorite | 4 |

| Sphalerite | 3.5-4 |

| Chalcopyrite | 3.5-4 |

| Lepidolite | 2.5-3 |

| Apatite | 5 |

| Pyroxene | 5-6 |

| Amphibole | 5-6 |

| Obsidian | 5-5.5 |

| Lapis Lazuli | 5-5.5 |

| Magnetite | 5.5-6.5 |

| Hematite | 5.5-6.5 |

| Opal | 5.5-6.5 |

| Moonstone | 6-6.5 |

| Pyrite | 6-6.5 |

| Feldspar | 6 |

| Jade | 6-7 |

| Tanzanite | 6-7 |

| Peridot | 6.5-7 |

| Garnet | 6.5-7.5 |

| Olivine | 6.5-7 |

| Agate | 6.5-7 |

| Onyx | 6.5-7 |

| Quartz | 7 |

| Amethyst (a variety of Quartz) | 7 |

| Citrine (a variety of Quartz) | 7 |

| Tourmaline | 7-7.5 |

| Aquamarine (Beryl) | 7.5-8 |

| Zircon | 7.5 |

| Topaz | 8 |

| Corundum | 9 |

| Diamond | 10 |

Practical Applications: How the Jewelry Industry Uses the Mohs Scale

The Mohs Hardness Scale is more than just a classification of mineral hardness. It’s a crucial tool for the jewelry industry. Whether it’s for designing, manufacturing, or repairing, understanding a gem’s hardness is vital to its treatment and care. Let’s delve into how the Mohs Scale impacts the world of jewelry.

The Design and Manufacturing Process

When jewelry designers conceptualize a piece, they need to consider the durability and wear of the gems involved. A gem’s position on the Mohs scale informs how it can be set, cut, and mounted. For instance, diamonds, which sit at a perfect 10 on the Mohs scale, are versatile and can be used in a variety of jewelry settings. In contrast, gems with a lower hardness might be set in areas with less wear, like pendants, or protected settings like bezels or halo designs.

Repair and Restoration

Repairing and restoring vintage or damaged jewelry requires a deep understanding of a gemstone’s hardness. When a jeweler works on a piece, they must know the limitations of each stone. Applying too much pressure or using certain tools on softer gems can result in scratches or damages. Being informed about the Mohs scale ensures that jewelers treat each gem with the care it needs.

Gemstone Durability and Daily Wear

For consumers, the Mohs scale is a guide to the practicality of everyday wear. Rings, for instance, are subjected to a lot of daily abuse. Gems that rank higher on the scale, like corundum (rubies and sapphires) or diamonds, are suitable for rings. On the other hand, softer gems might be reserved for earrings or necklaces, which experience less direct contact and potential abrasion.

Jewelry Care and Maintenance

Caring for jewelry also relies heavily on understanding gem hardness. For instance, ultrasonic cleaners are excellent for cleaning harder stones but can damage or even shatter softer gems. When consumers are informed about the Mohs rating of their gemstones, they can make better decisions about cleaning and storing their prized possessions.

In conclusion, the Mohs Hardness Scale is not just a theoretical tool for mineralogists. It plays a pivotal role in ensuring that the beauty and brilliance of jewelry pieces are preserved for generations to come.

Beyond Jewelry: Other Industries and Uses of the Mohs Hardness Scale

While the Mohs Hardness Scale is integral to the jewelry world, its applications stretch far beyond that domain. Numerous industries and sectors leverage the Mohs scale to evaluate materials, ensuring their proper use, durability, and treatment. Let’s explore some of these broader applications:

Construction and Building

The construction industry frequently employs the Mohs scale to determine the suitability of minerals for different building purposes. For instance, granite, which contains quartz (Mohs hardness of 7), is a popular choice for countertops due to its resistance to scratching. Similarly, softer stones like marble or limestone, which can be scratched more easily, are often treated or sealed to improve their durability when used as flooring or facades.

Industrial Manufacturing

In the realm of manufacturing, material hardness often dictates the type of tools or processes required. Whether it’s drilling, cutting, or grinding, understanding a material’s hardness can help prevent damage and optimize production efficiency. Furthermore, certain industries utilize minerals as abrasives; the hardness of these minerals directly impacts their effectiveness in tasks like sanding, polishing, or cutting.

Cosmetics and Personal Care

Interestingly, the Mohs scale also has relevance in the cosmetic industry. Minerals, particularly mica and talc, are used in products like eyeshadows and face powders. Their position on the Mohs scale provides insight into their texture, with softer minerals typically yielding a smoother finish on the skin.

Education and Research

Educational institutions and research centers use the Mohs scale as a foundational tool in geological studies. Students and researchers alike employ the scale to classify and identify minerals, fostering a deeper understanding of Earth’s vast mineralogical diversity.

Archaeology

In archaeology, the Mohs scale assists in the identification and dating of artifacts made from stone or metal. By assessing an object’s hardness and comparing it to the known hardness of certain materials from specific periods, archaeologists can glean insights into an artifact’s origin and age.

In essence, the Mohs Hardness Scale’s influence reaches far beyond the glittering world of gemstones and jewelry. Its principles underpin a myriad of applications, underscoring its universal value in understanding and working with the Earth’s mineral treasures.

Limitations of Mohs Scale: When and Why It Isn’t the Perfect Measure

The Mohs Hardness Scale is a renowned tool for classifying the hardness of minerals, but like all systems, it isn’t without its imperfections. Understanding the scale’s limitations is crucial for a comprehensive grasp of its applications and for recognizing scenarios where alternative methods might be more appropriate.

A Relative, Not Absolute, Measure

It’s pivotal to comprehend that the Mohs scale is relative and not absolute. This means that while it can specify that one mineral is harder than another, it doesn’t quantify the precise difference in hardness between them. For instance, diamond (10 on the Mohs scale) is several times harder than corundum (9 on the Mohs scale), even though their scale values are just a single unit apart.

Lack of Precision

The scale consists of ten fixed data points, which can lead to a lack of precision. Minerals that may have slightly varying hardness levels could end up with the same value on the Mohs scale simply because there’s no finer gradient to represent them.

Not Suitable for All Materials

While the Mohs scale is ideal for minerals, it’s less effective for gauging the hardness of industrial materials like alloys or composites, which might have varying hardness due to their mixed components.

Variability Within a Single Mineral

Some minerals can exhibit different hardness values depending on their specific orientation or the presence of impurities. For instance, kyanite is unique in having a distinct hardness when scratched along its length compared to its width. This variability can make accurate hardness determinations challenging.

Other Factors Impacting Durability

Hardness is only one aspect of a material’s overall durability. Other properties, such as toughness, brittleness, or elasticity, play pivotal roles in determining how a substance will fare under specific conditions. Solely relying on the Mohs scale might provide an incomplete picture of a mineral’s overall resilience.

In conclusion, while the Mohs Hardness Scale is an invaluable tool in the world of geology and mineralogy, it’s essential to recognize its boundaries. Professionals often complement it with other testing methods to get a holistic understanding of a material’s properties.

Alternative Hardness Measures: Understanding the Vickers and Brinell Scales

While the Mohs Hardness Scale is widely recognized, especially in mineralogy, other industries require more precise or diverse hardness testing methods. The Vickers and Brinell scales are two such systems used predominantly in metallurgy to determine the hardness of metals and alloys.

The Vickers Hardness Test

The Vickers Hardness Test, sometimes termed as microhardness test, utilizes a diamond indenter with a square-based pyramid shape. The test measures the diagonal length of the indentation left after applying a specific load to the material for a set duration. The Vickers Hardness Value (HV) is then calculated using a formula.

- Advantages: It can be used for all metals and has a wide scale range, making it versatile.

- Disadvantages: Requires specialized equipment and can be more time-consuming than some other methods.

The Brinell Hardness Test

The Brinell test uses a hard steel or carbide ball that’s pushed into the material under a specific load. The diameter of the indentation left on the specimen is then measured, and the Brinell Hardness Number (BHN) is derived from this measurement.

- Advantages: It provides reliable data on bulk metal properties and is suitable for rougher materials where a clear indentation is achievable.

- Disadvantages: Not suitable for harder materials like hardened steel, as they can damage the indenter.

Comparing with Mohs

While the Mohs scale is primarily qualitative and based on fixed minerals, both Vickers and Brinell are quantitative, allowing for more detailed comparisons between materials. They’re also largely used in industrial contexts, helping engineers and manufacturers determine the suitability of metals for specific applications.

Understanding the differences between these scales is paramount for professionals in various industries. While Mohs remains the go-to for mineralogy, Vickers, Brinell, and others (like Rockwell) are invaluable in the realm of metallurgy and engineering.

Conclusion: The Lasting Impact and Relevance of Mohs Hardness Scale in Modern Times

When Friedrich Mohs introduced his hardness scale in the early 19th century, he might not have anticipated the profound and lasting impact it would have across diverse sectors. From mineralogists to jewelry designers, the Mohs Hardness Scale has remained a cornerstone for classifying and understanding the relative hardness of minerals.

Its simplicity and qualitative nature have made the scale easy to teach and understand. Generations of geology students have relied on it as an initial tool for mineral identification, and jewelers have used it to determine the durability of gemstones in various settings.

While the scale has its limitations, and other measures of hardness like Vickers, Brinell, and Rockwell have since been developed for more specific and quantitative needs, the Mohs scale remains unique. Its power lies in its universality and ease of use, allowing even non-professionals to get a quick grasp of the concept of mineral hardness.

In our modern age, where advanced technological tools and methods seem to overshadow traditional ones, the continued relevance of the Mohs scale stands as a testament to its foundational importance. It serves as a reminder that sometimes, simplicity paired with utility can create tools that stand the test of time, bridging the past, present, and future of scientific exploration.

Frequently Asked Questions

Why did Friedrich Mohs develop the hardness scale?

Friedrich Mohs developed the hardness scale to provide a systematic and straightforward method for identifying minerals. By comparing the ability of one mineral to scratch another, he categorized them based on their relative hardness. This made mineral identification more practical and consistent for geologists and gemologists.

Is the Mohs scale used for materials other than minerals?

Primarily, the Mohs scale is designed for minerals. However, it has been applied to other materials to give a general idea of their hardness relative to minerals. For instance, human fingernails have a hardness of about 2.5, and a steel file has a hardness of approximately 6.5 on the Mohs scale. While the scale provides a relative hardness comparison, it’s essential to remember its primary application is for minerals.

Why is diamond ranked as the hardest mineral on the Mohs scale?

Diamond is ranked as the hardest mineral because of its unique crystal structure. Composed entirely of carbon atoms arranged in a tetrahedral pattern, this structure creates very strong covalent bonds between the carbon atoms, resulting in an incredibly hard material. As a result, no other naturally occurring substance can scratch a diamond, making it the hardest known mineral on Earth.

How does the Mohs scale compare to other hardness scales?

The Mohs scale is a qualitative scale based on a mineral’s ability to scratch another mineral. In contrast, other scales, like the Vickers and Brinell scales, are quantitative and involve measurements using specific machinery. These scales provide precise hardness values based on resistance to indentation or other factors. While the Mohs scale is valuable for its simplicity and ease of use in the field, other scales offer a more nuanced and technical understanding of material hardness.

Can the Mohs scale predict how a mineral will behave under industrial conditions?

The Mohs scale provides a general indication of a mineral’s resistance to scratching. However, it doesn’t necessarily predict other mechanical properties, such as tensile strength, fracture toughness, or resistance to wear in industrial conditions. For detailed predictions about mineral behavior under specific conditions, other mechanical and physical tests would be required.

Are there any minerals with hardness values between the whole numbers on the Mohs scale?

Yes, many minerals have hardness values that fall between the whole numbers on the Mohs scale. For example, while gypsum is rated at 2 and calcite at 3, some minerals might have a hardness of 2.5. These fractional values can help further differentiate minerals and provide a more accurate assessment of their hardness.

Why isn’t the Mohs scale linear?

The Mohs scale is ordinal and qualitative, meaning it ranks minerals based on their ability to scratch others, but it doesn’t measure the actual hardness difference between levels. So, while the difference between talc (1) and gypsum (2) might be relatively small, the difference in hardness between corundum (9) and diamond (10) is significantly more substantial. As such, the scale isn’t linear; the gaps between numbers can vary considerably.

Can two minerals of the same hardness scratch each other?

Yes, two minerals of the same hardness can scratch each other. The Mohs scale is based on relative hardness, so if two minerals are of equal hardness, their edges or points can cause abrasions or scratches on each other. This principle is often used by geologists in the field to help identify minerals.

Is it possible for a gemstone to have different hardness values on different crystal faces?

Yes, some crystals, like the diamond, exhibit different hardness values on different crystal faces, a phenomenon known as directional hardness. For diamonds, certain crystal directions are harder than others due to its unique crystal structure. This characteristic is vital for gem cutters, as it influences how a gem is shaped and faceted.

How does the Mohs scale impact the jewelry industry in choosing gemstones for various types of jewelry?

The Mohs scale plays a pivotal role in the jewelry industry, helping jewelers determine the durability of gemstones. Gemstones with higher hardness are more resistant to scratches and abrasions, making them ideal for jewelry pieces like rings or bracelets that face frequent wear and tear. Conversely, softer gemstones might be better suited for earrings or pendants, which have a lower risk of damage. Understanding a gemstone’s hardness ensures its longevity and beauty are preserved in the chosen jewelry setting.